Introduction

The growing global waste crisis has led to an urgent need for effective waste management solutions. Landfills are reaching capacity, and the environmental damage caused by excessive waste disposal is alarming. One of the most efficient ways to combat this issue is by optimizing waste recycling through compacting and baling technologies. A vertical baling press plays a significant role in reducing landfill dependence by enabling efficient recycling, minimizing waste volume, and promoting a circular economy. This article explores how vertical balers contribute to reducing landfill waste, their benefits, and their growing importance in sustainable waste management.

Understanding Vertical Baling Press

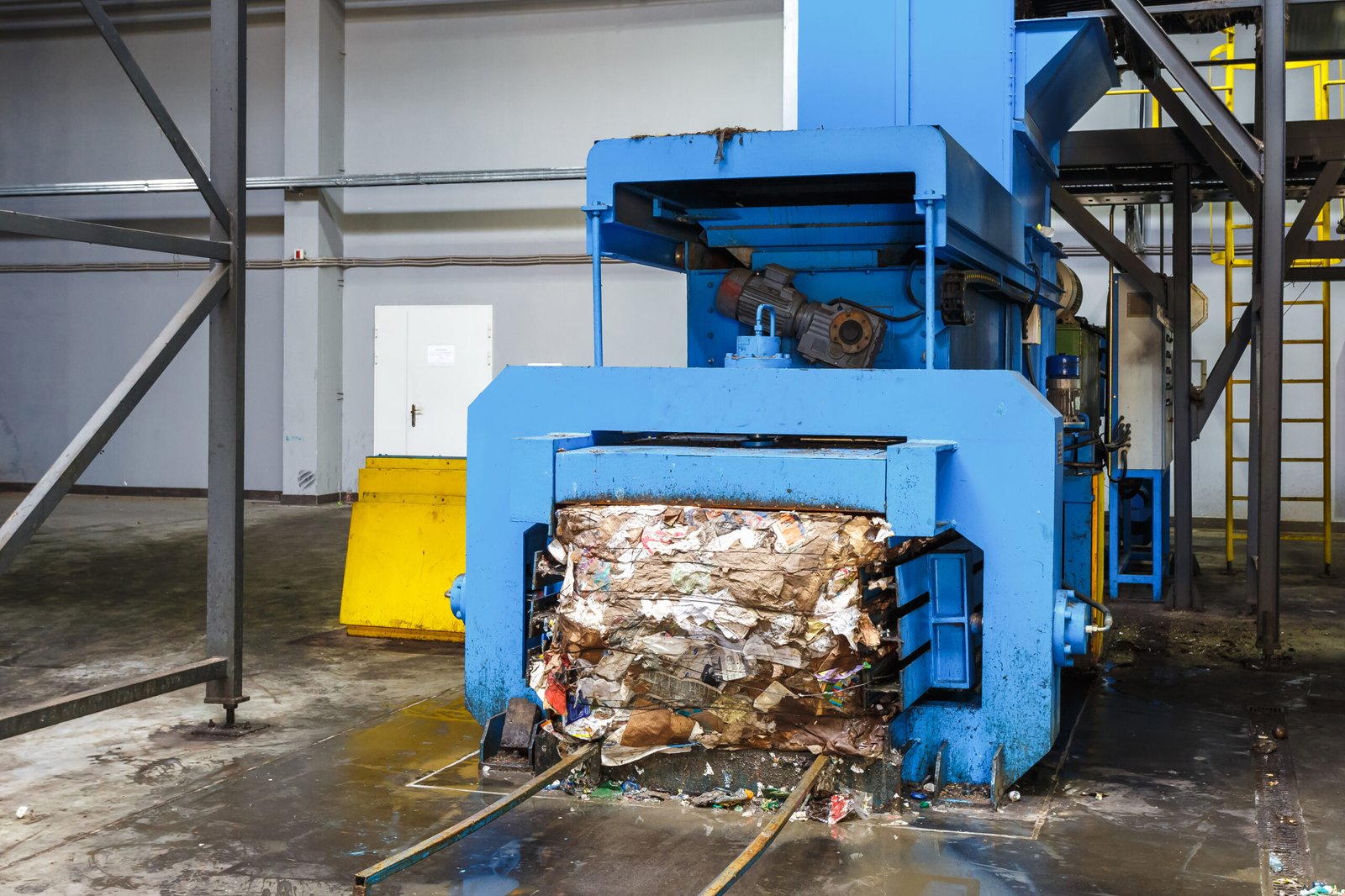

A vertical baling press is a compacting machine that compresses various recyclable materials into dense, manageable bales. Unlike horizontal balers, which require more space and are often used in large-scale industrial operations, vertical balers are space-efficient and ideal for small to medium-sized businesses. These machines handle a wide range of materials, including cardboard, plastics, textiles, aluminum cans, and other recyclable waste.

By using hydraulic or pneumatic pressure, a vertical baler significantly reduces the volume of waste, making storage, transportation, and recycling more efficient. The adoption of these machines has been instrumental in shifting from traditional waste disposal methods to sustainable recycling practices.

How Vertical Baling Press Reduces Landfill Dependence

1. Volume Reduction and Efficient Waste Management

One of the primary ways a vertical baling press helps reduce landfill dependence is by decreasing the volume of waste. Uncompacted waste takes up excessive space, leading to overfilled dumpsters and higher transportation costs. By compressing waste materials into dense bales, vertical balers significantly reduce the physical space required for storage and disposal.

Compact bales allow businesses to transport large amounts of recyclable materials efficiently, reducing the frequency of waste collection trips. This not only lowers carbon emissions from transportation but also minimizes the overall burden on landfills by diverting recyclable waste from disposal sites.

2. Encouraging Recycling and Resource Recovery

A major contributor to landfill waste is the improper disposal of recyclable materials. Paper, cardboard, plastics, and metals often end up in landfills due to the lack of proper recycling processes. A vertical baling press enables businesses to segregate and compact recyclables, making it easier for recycling facilities to process them efficiently.

By creating neatly compressed bales, the vertical baler ensures that waste materials remain uncontaminated, increasing their value in the recycling market. This encourages businesses to participate in recycling initiatives, reducing the amount of waste that ultimately ends up in landfills.

3. Lowering Waste Disposal Costs

Traditional waste disposal methods involve significant costs associated with landfill tipping fees, waste transportation, and regulatory compliance. With stricter environmental regulations and increasing landfill taxes, businesses are looking for cost-effective alternatives.

A vertical baling press helps reduce waste disposal expenses by decreasing the volume of waste and promoting recycling. Companies that use vertical balers often generate revenue from selling baled recyclables to processing plants, further offsetting waste management costs. This financial benefit motivates organizations to shift from landfill-dependent waste disposal to sustainable recycling practices.

4. Reducing Greenhouse Gas Emissions

Landfills are a significant source of methane, a greenhouse gas that is far more potent than carbon dioxide in contributing to climate change. Organic waste decomposes anaerobically in landfills, releasing methane into the atmosphere. By diverting recyclable and compostable materials away from landfills through the use of vertical baling press, businesses and municipalities can significantly cut down on methane emissions.

Additionally, manufacturing new products from recycled materials requires less energy compared to producing goods from virgin resources. By facilitating efficient recycling, vertical balers contribute to energy conservation and overall carbon footprint reduction.

5. Enhancing Corporate Sustainability and Compliance

Sustainability has become a core focus for businesses worldwide. Companies that actively reduce landfill waste through recycling and waste minimization efforts enhance their corporate social responsibility (CSR) profile. A vertical baling press helps businesses meet sustainability targets by ensuring proper waste segregation and recycling practices.

Moreover, many industries must comply with stringent waste management regulations. Using vertical balers ensures that organizations adhere to environmental standards and avoid penalties associated with improper waste disposal. The adoption of such machines demonstrates a commitment to sustainability and responsible waste management practices.

6. Supporting Circular Economy Initiatives

A circular economy aims to keep materials in use for as long as possible through recycling, repurposing, and reducing waste. The vertical baling press is an essential tool in supporting this model by transforming waste into valuable resources.

By compacting recyclables into standardized bales, the vertical baler streamlines the supply chain for recycled materials, ensuring a steady flow of raw materials for industries that rely on recycled inputs. This reduces the need for virgin resource extraction and promotes a more sustainable manufacturing cycle.

Industries Benefiting from Vertical Baling Press

Several industries have embraced vertical baling press technology to reduce landfill dependence and improve waste management efficiency. Some of these include:

- Retail and Supermarkets: Cardboard and plastic waste are common in retail stores and supermarkets. Vertical balers help compact packaging waste, making recycling more manageable.

- Manufacturing and Industrial Facilities: These industries generate large quantities of scrap materials, such as metals and plastics. Vertical balers ensure efficient waste handling and recycling.

- Textile and Fashion Industry: Fabric waste and discarded textiles can be baled and repurposed for recycling, reducing textile waste in landfills.

- Hospitality and Food Service: Restaurants, hotels, and catering services benefit from vertical balers by compressing packaging waste and reducing disposal costs.

- Healthcare and Pharmaceuticals: Hospitals and medical facilities generate recyclable materials, including packaging waste and used paper. Vertical balers help in proper waste segregation and disposal.

Conclusion

The vertical baling press is a game-changer in modern waste management, significantly reducing landfill dependence by promoting recycling, minimizing waste volume, and cutting down greenhouse gas emissions. Businesses and industries that incorporate vertical balers into their waste management strategies benefit from cost savings, regulatory compliance, and enhanced sustainability initiatives.

As the global focus on environmental conservation intensifies, adopting technologies like vertical balers will be crucial in achieving waste reduction goals and creating a more sustainable future. By investing in vertical baling press, businesses can take a proactive step towards responsible waste management while contributing to a cleaner, greener planet.